We don't think about how our clothes are made. We see a t-shirt at a store, we probably check the price - and if we like it, we buy it. Rarely do we stop and think about where that t-shirt was made, or what materials were used or under what conditions it was produced.

|

| Rana Plaza building collapse in Savar, Bangladesh - Image via Wikipedia |

Then suddenly terrifying pictures of young seamstresses jumping out of burning factory windows in Pakistan and rescue services pulling dead bodies out of the ruins of a collapsed factory building in Bangladesh pollute our news and we are shocked. We think 'that must be terrible for the families!' and 'what if that happened here?' - but we don't realize: These people died stitching the hem on the exact t-shirts we were going to buy a couple of months later. Even though we all know that most of our garment production takes places in South East Asia, Bangladesh and Pakistan are just too far away to fully grasp the impact of such devastating incidents. When we do get the occasional sting of guilt, we justify our lack of initiative with the deterministic question: 'But what can we - as simple consumers - really do?'

About 100 years ago, when such a disaster happened right in our midst, we knew what to do: Looking back on the fire in the Triangle Shirtwaist Factory in 1911 right here in Manhattan puts a whole new perspective on the fashion industry's marvelous idea of outsourcing (or: off-shoring) all the time-consuming sewing work to foreign countries marked by devastating poverty and desperate people living below the breadline - foreign countries that are also conveniently far, far away. With the ignorant motto of 'out of sight, out of mind' the fashion industry has managed to put the consumer's mind at ease - and reduce the garments' prices all at the same time. Seems like a win-win situation.

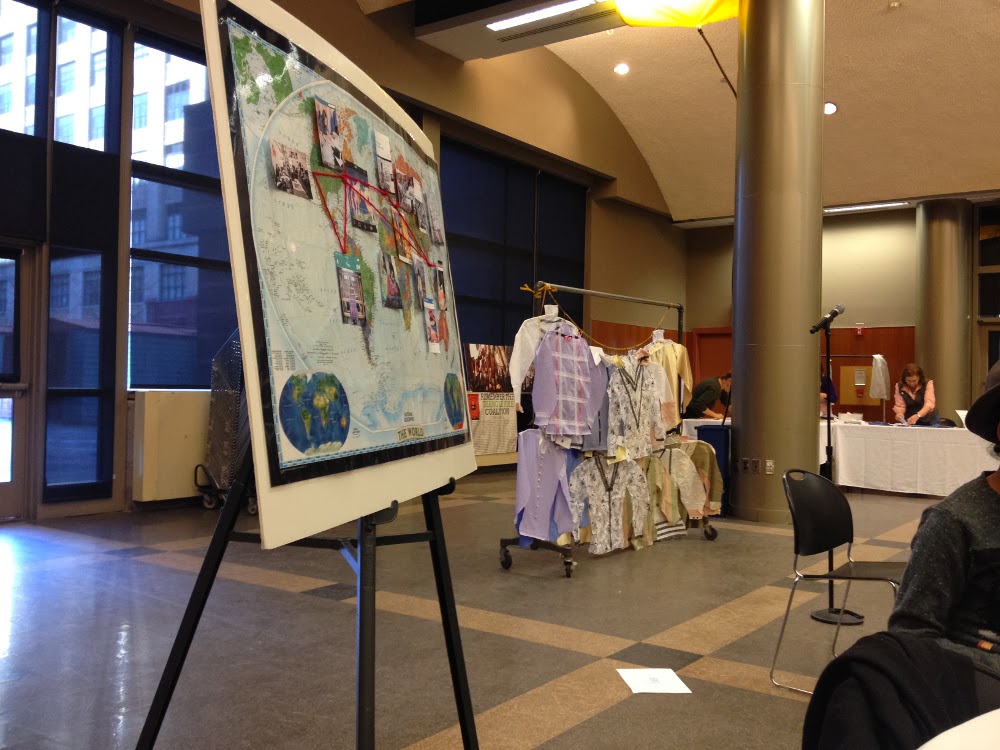

If I learned one thing from today's conference 'Factory Safety - What can we do?' at the Fashion Institute of Technology in NYC, it is that this current situation is not a win-win situation. Among corporate social responsibility (CSR), sustainability and eco-friendliness, the conference focused on the comparison of today's incidents in South East Asia with the disaster of 1911 in New York - and what we can do to help. It was also possible to design and create one's own shirtwaist banner that would be carried at the Triangle Shirtwaist Factory fire memorial ceremony on March 25.

|

| Shirtwaist banners designed and created by conference participants |

The participants were able to discover both the corporate side of CSR with guest speaker Marissa Pagnani who represented PVH and also the academic side with a panel of FIT faculty and students who founded the university's own CSR Club (that I joined!). All throughout the conference, participants were encouraged to voice their opinions and join the discussion, which communicated very nicely that all of us are in this together. Last but not least, Charles Kernaghan, the Director of the Institute for Global Labour and Human Rights, talked about his work.

Kernaghan started off by telling us about the fire in the Triangle Shirtwaist Factory that caused young - mostly immigrant - seamstresses to jump from the 8th, 9th and 10th stories of the Asch building on the northwest corner of Greene Street and Washington Place in Manhattan - because the emergency exits were locked - in order to not be fully consumed by the deadly flames and to ensure that their families would be able to identify them after their death. Does this sound familiar to you?

|

| The Triangle Shirtwaist Factory after the fire in 1911 - Image via Public History Blog |

Back then, the fire took the lives of 146 garment workers - 123 female, 23 male - and set the stone for a political movement towards safety standards. Unions were organized, specifically the International Ladies' Garment Workers' Union, that helped improve unfair working conditions for garment workers. By 1938, sweatshops were virtually eliminated in the US until the 1980s when the fashion industry began to outsource its production to South East Asia, which, so Kernaghan, ruined all the progress made in previous years.

The accident of the collapsed Rana Plaza building in Savar, Bangladesh, on April 24, 2013, took 1,129 lives and was only the latest of a serious of deadly accidents in factories in South East Asia - but still barely any changes have been made so far. Even though the companies that produced at these factories are trying to improve working conditions in collaboration with the Accord - by auditing and monitoring the factories to make sure that no emergency exits are being locked and that enough fire extinguishers are available, for example - there is still more to be done. The Bangladeshi government still doesn't grant its people the right to organize, which gives them no form of representation and no way of standing up against the factory owners and supervisors in face of unfair working conditions. Before the implementation of a minimum wage, the workers at the Triangle Shirtwaist Factory earned $3.18/hour (for today's standards), while the workers in Bangladesh today earn only $0.28/hour.

|

| Charles Kernaghan - Director of the Institute of Global Labor and Human Rights |

In 2009, the American Congress passed a law - the Dog and Cat Protection Act - that prohibits the import of dog and cat fur from China into the US - but we can't protect humans with a similar law? Businesses owners are allowed to protect clothing labels by law but not the workers who produce the garments because that would be 'an impediment to free trade?' Why are we supporting these businesses, such as Walmart, Sears and the Gap, that exploit garment workers for cheaper prices and higher margins? Is a low price really all that matters to us? Are Bangladesh and South East Asia really that far away that we can't empathize with and support the struggling people there?

These are all questions that can't be easily answered but the unified message of all speakers seemed to be that the progress of this movement is, indeed, up to us. We need to inform and educate ourselves about the companies we buy from, about their production processes and their CSR programs. We need to make educated buying decisions taking these factors into account and use our buying power for the good. The change won't happen over night but if we all participate, we can make a difference.

No comments:

Post a Comment